2024/01/09

Steel type and description of common bearing materials

Section steel. According to the section shape, it is divided into round steel, flat steel, square steel, hexagonal steel, octagonal steel, angle steel, I-beam, channel steel, T-beam, B- beam, etc.

Key words:

2024/01/09

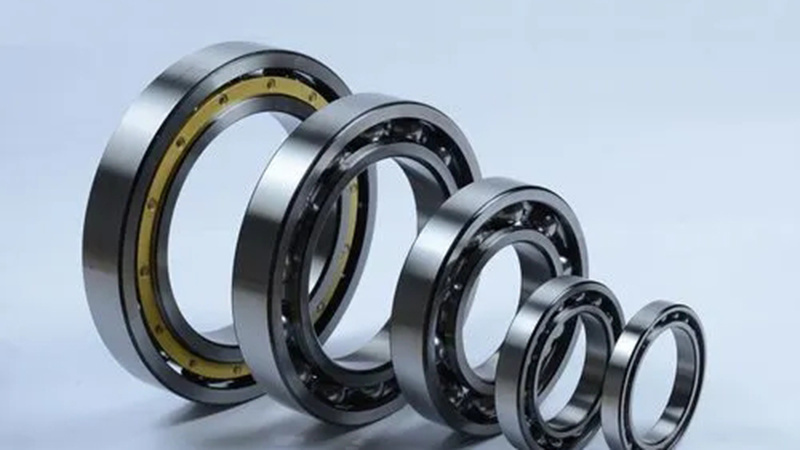

Bearing (Bearing) is an important part of contemporary mechanical equipment. According to the different friction properties of moving elements, bearings can be divided into two categories: rolling bearings and sliding bearings. Among them, rolling bearings have been standardized and serialized, but compared with sliding bearings, their radial size, vibration and noise are larger, and the price is higher. The tension wheel bearing is actually an ordinary bearing but the structure is different.

Key words:

2024/01/09

The Importance of Sealing of Spherical Roller Bearings

The sealing of the bearing is to maintain good lubrication conditions and normal working environment of the spherical roller bearing, give full play to the working performance of the bearing, and extend the service life. The rolling bearing must have a suitable seal to prevent the leakage of lubricant and dust, Intrusion of moisture or other dirt.

Key words:

2024/01/09

Influence of Bearing Structure on Vibration and Noise

Falling body rolling sound, the noise is generally found in large bearings that are under low speed and bear radial load. When the bearing is running under radial load, the load area and non-load area in the bearing. If the bearing has a certain radial clearance, the rolling elements in the non-load area do not contact the inner raceway, but may contact the outer ring due to centrifugal force. At low speed, when the centrifugal force is less than the dead weight of the rolling elements, the rolling elements will fall and collide with the inner raceway or cage to stimulate the inherent vibration and noise of the bearing.

Key words:

2024/01/09

General inspection method of bearing?

All kinds of mechanical scars, such as abrasion, scratch, crush, bruise, etc., will cause poor bearing installation, causing eccentric load and stress concentration, resulting in the decline of rotation accuracy and service life.

Key words:

2024/01/09

How to check the radial clearance of rolling bearings?

The measurement is carried out by the press lead method and the feeler gauge method. The translation of the radial clearance is not marked in the bearing code. The clearance of the bearing is different according to the size of its inner diameter. Look-up table to determine that under normal circumstances, the radial clearance of the rolling bearing cannot be greater than 3‰ of the inner diameter of the bearing, and the radial clearance of the radial short cylindrical bearing cannot be greater than 2‰ of the inner diameter of the bearing.

Key words:

2024/01/09

Maintenance methods of mechanical bearings

Bearings are quite common in our lives. Bearings are an important part of mechanical equipment, but various problems will inevitably occur during use. In mechanical equipment, the state of the engine affects the service life and work efficiency of the mechanical equipment. Has a direct impact.

Key words:

2024/01/09

Fault Analysis of Sliding Bearing

The sliding bearings in the mechanical equipment of the cement plant are mainly copper tiles, babstet tiles, phenolic resin tiles, and the main failure forms of sliding bearings are heating, abnormal wear, and burning tiles. The failure mode of sliding bearing is closely related to the scraping method and the corresponding lubrication mechanism.

Key words:

2024/01/09

The choice of bearing external seal should consider the following main factors

According to the requirements of the bearing working condition and working environment on the sealing degree, various sealing forms are often used comprehensively in engineering design to achieve better sealing effect.

Key words:

2024/01/09

To ensure that the bearing can work reliably, pay attention to the following points

From the perspective of use, to ensure that the bearing can work reliably, pay attention to the following points: 1. Improve lubrication quality, control oil pressure, temperature and flow, and strengthen oil filtration. 2. Adopt fuel oil and lubricating oil that meet the requirements. 3. Control the temperature state of the diesel generator set, and it is unfavorable to work in the case of overcooling and overheating. In cold weather, the diesel engine should be preheated before starting, and the crankshaft should be turned by hand to make the oil enter the friction surface. 4, bearing and journal surface quality and geometry should be strictly guaranteed. 5, the bearing clearance should be appropriate, the generator set is too large to produce impact, too small is poor lubrication, may burn tile.

Key words: